Cooling dryers | Airpress

Are you looking for a simple and efficient way to protect your pneumatic tools from the negative impact of moisture in compressed air? Or perhaps you're interested in a professional industrial dryer that will provide process air and protect your pneumatic system from corrosion? In both cases, Airpress offers a refrigerant dryer tailored to your needs. All of our refrigerant dryer models are designed for maintenance-free, highly efficient condensation of moisture and removal from compressed air. Each series meets the specific requirements of different user groups, utilizing high-quality components and advanced technologies. They share stability in operational parameters and high energy efficiency – the qualities most valued by professional users of compressed air systems.

Choose a refrigerant dryer directly from the manufacturer of reliable compressed air treatment systems!

Refrigerated Air Dryers by Airpress - Choose Quality!

Refrigerated air dryers are essential for compressed air treatment, ensuring the safe operation of pneumatic tools, machinery with pneumatic drives, and pneumatic actuators. Most importantly, they guarantee the smooth operation of all system components without failures.

These devices dry compressed air using the simplest and most economical refrigeration method. In this process, air is cooled to condense water vapor—this moisture is then separated and removed from the compressed air. Thus, refrigerated dryers are also commonly referred to as condensate or cooling dryers.

Simple operation and high moisture separation efficiency have made refrigerated dryers an integral component in screw compressors used in workshops, production, and industrial settings. Like other equipment that operates based on physical laws, the quality and usability of a refrigerated air dryer depend not only on the core process but also on its design, materials, components, and technologies used.

At Airpress, we specialize in designing and installing high-performance, energy-efficient pneumatic systems. We fully understand the destructive impact moisture in compressed air can have on the entire system. That’s why we’ve worked hard to ensure that our refrigerated dryers are a model example of effective, efficient, and energy-saving solutions for compressed air treatment.

Try our selected models in your company—you’ll notice the difference in the air quality!

Stable Operating Parameters & Guaranteed Minimal Pressure Drops

Modern heat exchangers and cooling units ensure the high stability of the operational parameters of our refrigerated air dryers. Efficiently positioned fans continuously regulate the airflow, stabilizing the dew point (PDP). This ensures maximum reduction in pressure drops, which can be very costly, especially in industrial applications.

Process Air Compliant with ISO 8573-1 Standard

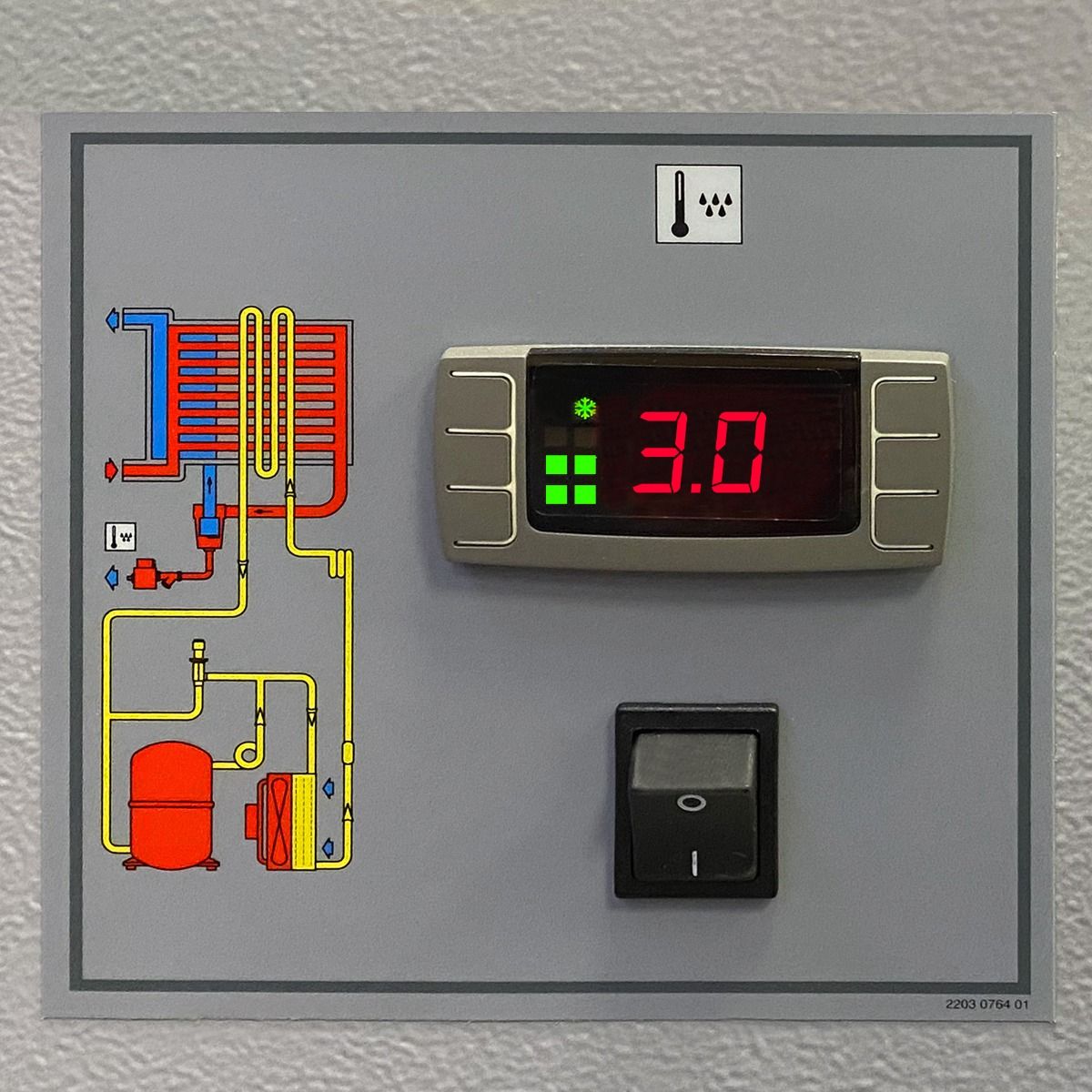

All Airpress refrigerated dryers achieve a pressure dew point (PDP) of +3°C, allowing them to generate compressed air Class 4 for moisture according to ISO 8573-1 (up to 6g H2O/m3). This class is required for process air used in many applications—ranging from general workshop air, pneumatic tools, CNC machine drives, pneumatic actuators, and paint systems, to advanced control systems, packaging, and pneumatic transport systems.

Full Automation & Low Operating Costs

Airpress refrigerated dryers come with automatic condensate drains, making them virtually maintenance-free with low operational costs. Additionally, all models are equipped with modern sensors and intelligent controllers that allow real-time monitoring of dryer parameters (pressure, temperature, etc.). The control panels are intuitive and easy to use, even for less experienced operators.

Environmentally Friendly Refrigerants Only

The heat exchanger cycle in our refrigerated dryers is filled with ozone-safe refrigerants that have a low GWP (Global Warming Potential). Combined with low energy consumption, our dryers are one of the most eco-friendly elements in the compressed air treatment system.

Refrigerated Air Dryer - APX Series

Basic models of refrigerated dryers, designed for use in mechanical, automotive workshops, and other service facilities that rely on pneumatic tools daily.

They are perfect for applications with stable operating conditions where the load on the dryer remains constant. Thanks to their compact and lightweight design, APX series dryers are easy to transport and adapt, even in small spaces.

Standard APX refrigerated dryers from Airpress offer optimal protection for your tools, equipment, and less complex systems against moisture, corrosion, and costly breakdowns!

Maximum Pressure: 14 bar / 16 bar

Maximum Inlet Air Temperature: 55°C

Ambient Temperature Range: 5°C - 43°C

Refrigerants: R410A / R452A / R513A

Aluminum Heat Exchanger

By utilizing high-quality aluminum heat exchangers, we have successfully optimized the efficiency of our air dryers while minimizing pressure losses.

The efficient refrigeration unit is protected from thermal overload and cooled by a refrigerant, with its capacity continually monitored by a precise hot gas bypass valve.

Thanks to premium components, the APX series air dryers offer reliability, a consistent dew point pressure, low maintenance requirements, and extended service intervals.

Two-Stage Moisture Separation System

Each APX air dryer cools compressed air using a standard two-stage heat exchanger. This traditional method has been significantly enhanced by using exchangers with larger heat exchange surfaces and higher thermal efficiency.

The condensate separated during the moisture separation process is automatically and without maintenance removed via a timed electronic condensate drain, ensuring no risk of pressure loss or work stoppages.

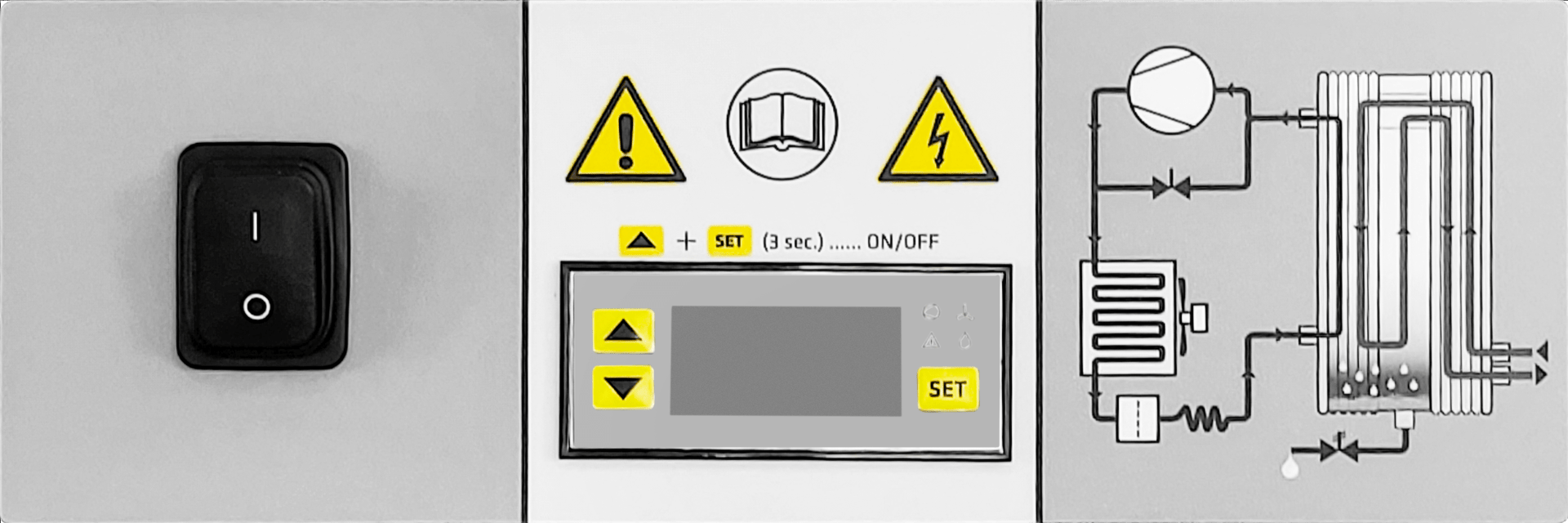

Electronic Control System

Each APX series air dryer is equipped with an electronic control system featuring a dual sensor monitoring dew point and condensation pressure. Depending on the model, the control panels offer varying levels of functionality, with more or less advanced parameter monitoring options. The panels differ in the alarm display.

The basic models alert you to too low/high PDP and fan probe failure, as well as reminding you of service dates.

APX 24-77 models additionally signal excessive refrigerant temperatures.

APX 100-840 models are equipped with functions for sensor failures and electrical faults. The controllers also include a high-pressure switch, an alarm for condensate drain issues, and remote on/off control.

The APX air dryer will effectively extend the lifespan of your compressed air system and all its components, helping you avoid costly service interventions and providing optimal protection against rust, corrosion, and even leaks.

Boost the productivity of your compressed air system and work efficiency – choose our APX air dryer!

Air Dryer - Series RDO

Advanced models of air dryers designed for use in larger pneumatic systems, primarily in manufacturing and industrial plants that rely on compressed air technology. These units are ideal for applications with unstable working conditions (varying load on the dryer).

Professional, industrial RDO series air dryers by Airpress offer reliable protection for your pneumatic system and all connected devices and systems from the harmful effects of moisture, premature wear, or serious breakdowns!

Maximum Pressure: 14 bar / 16 bar

Max Inlet Air Temperature: 55°C

Ambient Temperature Range: 1°C - 45°C

Refrigerant: R513A

3-Stage Moisture Separation System

Unlike standard models, each RDO series refrigeration dryer separates moisture through a 3-stage process. The 3-phase drying system includes a secondary heating of the outgoing air, which eliminates the risk of condensation forming outside the compressed air installation.

This provides an additional protection against corrosion and freezing, not only inside but also outside the system. This is particularly important when working in more challenging environmental conditions or with systems exposed to temperature fluctuations.

Furthermore, thanks to the 3-stage heat exchanger, the incoming air is first cooled by the already dried outgoing air, making the drying process more efficient.

Utilizing a 3-stage drying system allows for more effective and efficient moisture separation through refrigeration.

Due to more efficient moisture condensation, each RDO refrigeration dryer is equipped with an advanced condensate drain—an automatic, electronic sensor-based ZeroLoss drain.

The ZeroLoss condensate drains by Airpress ensure minimal pressure drops and eliminate the risk of compressed air losses during the drying process. This makes RDO refrigeration dryers a significant boost to the energy efficiency of the entire system.

Control Panel with MODBUS Communication

The RDO refrigeration dryers are equipped with a robust and user-friendly controller. The control panel is based on the MODBUS communication protocol, commonly used in various industrial automation applications.

The controller includes a digital output for the alarm signal and a digital input for remote control of the dryer (on/off). Additionally, the device can be switched to Stand-By mode.

The control system features advanced sensors for temperature and pressure, allowing the panel to display data on:

- dew point temperature,

- compressor outlet temperature,

- condensation temperature / condensation pressure.

The control system also includes an extensive alarm module, which continuously signals any issues in the dryer’s operation that could interfere with the smooth functioning of the entire system.

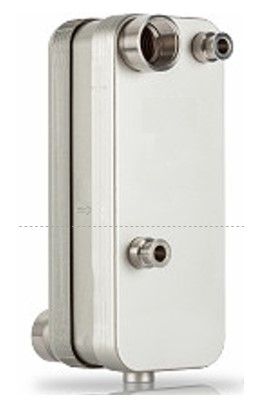

Stainless Steel Heat Exchanger

The use of a more efficient heat exchanger with enhanced energy efficiency has enabled us to improve the performance of the RDO refrigeration dryers. We’ve also ensured that it’s appropriately protected and suited for continuous operation.

The heat exchanger made of stainless steel is highly resistant to moisture damage, ensuring long-term, trouble-free operation of the dryer. Additionally, the exchanger is equipped with a built-in water separator. This helps maintain a stable dew point and allows energy savings!

The cooling unit with a heat exchanger ensures reliable compression of the refrigerant and further improves the air drying process. It is responsible for extreme condensation, where the highest amount of water is extracted from the air. For full operational safety, the unit is equipped with a built-in thermal module, which provides effective protection against overloading the device.

Smaller RDO dryers are equipped with compressors based on a piston compressor, while higher models use a screw compressor to compress the refrigerant.

The high-quality hot gas bypass valve continuously monitors the state of the refrigerant, maintaining a constant evaporator temperature even under varying load conditions. It also prevents freezing at low load or no load. The valve is factory-calibrated and does not require further adjustment.

High-Performance Cooling System

In addition to the heat exchanger, cooling unit, and bypass valve, the RDO refrigeration dryers feature high-performance coolers, which ensure reliable condensation control. Smaller models come with an NTC sensor, while larger models are equipped with an additional pressure switch.

The cooler lowers the refrigerant temperature with the help of air. If desired, we can provide an RDO refrigeration dryer with a water-cooling option.

The RDO dryers also feature:

- filter to absorb moisture and capture particles and other contaminants;

- device for reducing refrigerant pressure—either a capillary tube (in smaller models) or an expansion valve (in larger models).

All components and parts used in the production ensure optimal and energy-efficient cooling operation.

Highest Level of Safety

The RDO refrigeration dryers are rated at IP 68 protection class (International Protection Rating), meaning they are fully protected against dust, solid particles, and water. They also have high levels of waterproofing and water resistance.

All RDO dryers come equipped with necessary safety features, ensuring smooth, trouble-free operation.

In basic models, there is thermal protection for the compressor of the cooling unit, as well as additional thermal protection immediately behind it. In higher-performance models, the system includes high and low pressure switches located after the compressor.

This ensures maximum safety for the device, the entire system, and its operators!

The combination of a 3-stage stainless steel heat exchanger, innovative monitoring sensors for system parameters, and the intelligent control system ensures stable dew point pressure and efficient operation of the dryer, even in variable environmental conditions or with fluctuating system loads, without affecting the device’s performance.

Thanks to the unique combination of technology and functionality, the RDO refrigeration dryer guarantees minimal pressure losses and maximum system efficiency, with reduced operational costs.