Oil lubricated air compressor

Airpress Oil Compressors are devices that have enjoyed popularity for years among both DIY enthusiasts and professionals. Thanks to the use of oil lubrication for key mechanical components, such as pistons and crankshafts, these compressors are characterized by exceptional durability and efficiency. Moving and rotating parts, including the crankshaft, piston, bearings, and connecting rod, are lubricated with oil, preventing them from seizing during operation. The oil also absorbs combustion residues and metal particles that could contaminate the compressor and cause failure. It not only minimizes friction but also improves sealing within the compression chamber and effectively cools the compressed air. This makes oil-lubricated compressors more reliable and capable of operating at higher working pressures, making them suitable for both light household tasks and demanding industrial applications.

Due to their versatility, these compressors find applications in various fields. They are indispensable for tire inflation, spray painting, cleaning, and powering pneumatic tools such as screwdrivers and cutters. Larger models, equipped with spacious air tanks, allow for prolonged operation without interruptions, which is crucial for automotive workshops and industrial plants. Additionally, when equipped with water and oil separators, they are ideal for precision work such as painting, where high-quality clean air is required.

Airpress oil compressors offer an excellent combination of durability, performance, and reliability. Regular maintenance, such as oil changes, filter cleaning, and condensate removal, ensures a long service life and smooth operation. Choosing an oil compressor is an investment in a machine that can handle the toughest challenges and provide efficiency in any compressed air application. Explore our range of Airpress oil compressors and select the model that best meets your needs – reliability, durability, and performance are waiting for you!

Oil Compressors – The Widest Selection at Airpress

Oil compressors represent the largest category among piston compressors offered by Airpress. Our range includes a wide variety of models, covering nearly all piston compressor series. You can choose from units equipped with engines ranging from 0.3 to 20 HP and air tanks from 3 to an impressive 900 liters. Each model features outstanding technical specifications, making them suitable for a diverse range of applications.

The effective capacity of our oil compressors ranges from 32 to 1701 l/min, allowing users to select a machine that meets their needs – from light workshop tasks to demanding industrial applications. Additionally, certain models can reach maximum pressure levels from 7 to 14 bar, making them an ideal choice for both hobbyists and professionals seeking reliable solutions.

How Do Oil Compressors Work?

In oil compressors, key mechanical components such as pistons, crankshafts, and bearings are constantly lubricated with oil, minimizing friction and preventing wear. Furthermore, oil enhances the sealing of the compression chamber, improving compressor efficiency while cooling the compressed air to prevent overheating. As a result, oil compressors can operate at higher working pressures, often exceeding 8 bar, making them more versatile than oil-free models.

Applications of Oil Compressors

The versatility of oil compressors makes them useful in many fields. Depending on the model, they can be used for:

- Tire inflation – Reliable for automotive workshops, home garages, and agricultural machinery maintenance.

- Spray painting – Ideal for DIY projects, furniture renovations, and professional painting jobs.

- Sandblasting and cleaning – Efficiently removes rust, old paint layers, and tough dirt.

- Metal cutting and drilling – Perfect for workshops and industrial applications.

- Upholstery and woodworking – Great for powering pneumatic staplers and nail guns.

- Agricultural applications – Supports farm machinery operation and pneumatic tools.

Advantages of Oil Compressors

- Extended lifespan – Oil lubrication protects moving parts from wear.

- Higher efficiency – Ability to work at higher operating pressures.

- Versatile applications – Suitable for both light home tasks and heavy-duty industrial work.

Oil Compressor Maintenance – The Key to Reliability

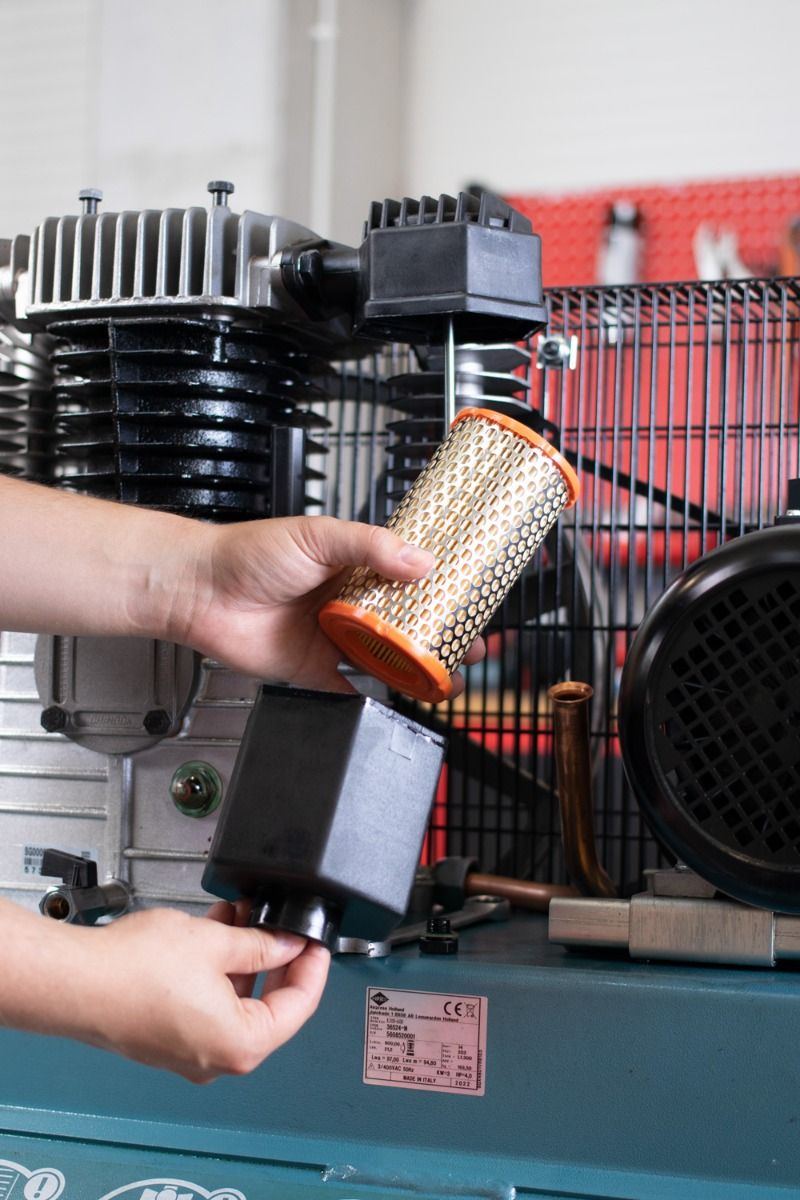

Regular maintenance of an oil compressor is essential for its long-term and efficient operation. One of the most critical aspects is regular oil changes, which prevent excessive wear on moving parts such as pistons and crankshafts. It is recommended to change the oil at least once a year, or more frequently if the compressor is used intensively.

Additionally, air filters should be regularly cleaned and replaced to protect the machine from contaminants and ensure optimal performance. Another crucial maintenance task is removing condensate from the air tank. Water accumulating inside the tank during operation can cause corrosion and degrade the quality of compressed air. Regularly draining condensate, combined with checking oil levels and connection seals, helps prevent costly repairs and ensures smooth compressor operation. By following the manufacturer's maintenance recommendations, you can enjoy reliable performance for many years.